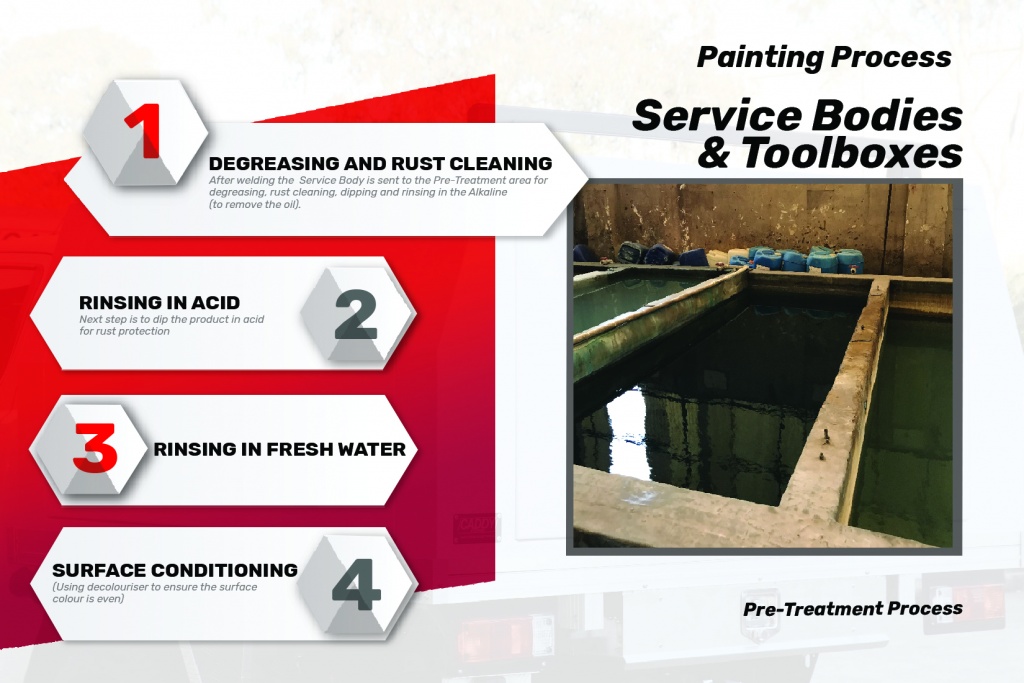

Below is the stringent process/steps we follow for pre-treatment and painting of our Aluminium Canopies.

- Step 1: Degreasing and Rust Cleaning – After welding the aluminium canopy is sent to the pre-treatment area for degreasing, rust cleaning, dipping and rinsing in the Alkaline (to remove the oil)

- Step 2: Rinsing in Acid – Next step is to dip the product in acid for rust protection.

- Step 3: Rinsing in the fresh water

- Step 4: Surface Conditioning – Using decolouriser to ensure the surface colour is even

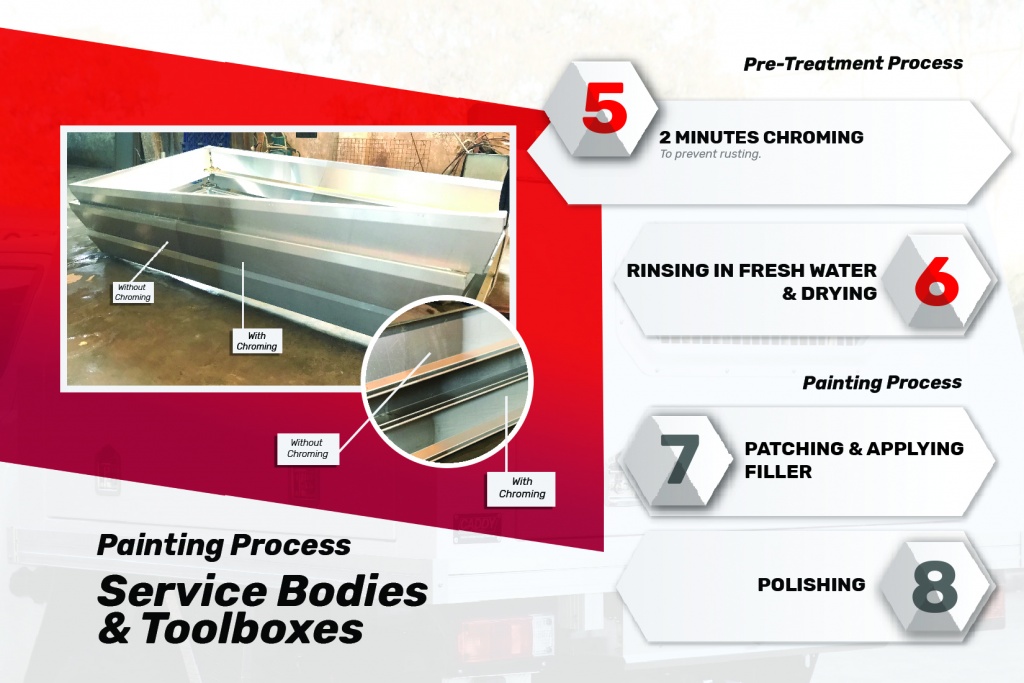

- Step 5: 2 minutes Chroming (to prevent rusting )

- Step 6: Rinsing in the fresh water & drying

- Step 7: Patching & applying filler

- Step 8: Polishing

- Step 9: Painting – Our Aluminium Canopies and Tool Boxes are manually painted. The small parts are painted automatically at the painting line.

- Step 10: Powder coating – To obtain a high gloss surface

- Step 11: Baked in oven: 10-12 minutes

- Step 12: Packing for protection