FAQ

Most frequently questions and answers

General Shelving

30 kgs per shelf evenly distributed.

Do not overload shelving. General cleaning and periodically checking the fasteners. It is also advisable to inspect mounting points especially top mounting points. If shelving is overloaded this can place stress on the vehicles cantrail. If any signs of stress or cracking of the cantrail please visit your local Caddy outlet as a matter of urgency.

0.9mm and 1.6mm zincanneal plated steel for shelving and end panels. 19mm x 19mm x 2mm RHS tubing for uprights. All powder coat finish.

Shelving is very dependant on different styles and what vehicle it is being installed into. A typical bay of shelving would take a skilled person between 1 – 1 ½ hours to install.

Yes, depending on the condition of the product and its compatibility to the new vehicle. Pricing will be quoted upon inspection. It will be based on an hourly labour rated and spare parts.

REFER TO WEBSITE https://www.caddystorage.com.au/contact/store-locator or contact your local branch for distributors in your area.

General Drawer System FAQ'S

Commonly 125kg load rating for large drawer / flat slide system however this can be upgraded if the requirement is there. Please enquire about a heavier duty drawer system if required. 30kg per shelf for small parts drawer systems.

It is most important not to over load your drawer system. If your drawer system is NOT overloaded, you should have no issues with this product. Periodically check functionality of rollers and locks. If drawers are not secured when vehicle is in motion there is a chance of damage to rollers, runners and lock systems. Many drawer issues are based around the operator not securing the system prior to driving their vehicle.

Generally our drawer systems are secured in place in the vehicle not to be easily removed. If there is a requirement for an easier removable system then is SOME cases this may be able to be designed.

General Roof Rack FAQ'S

-

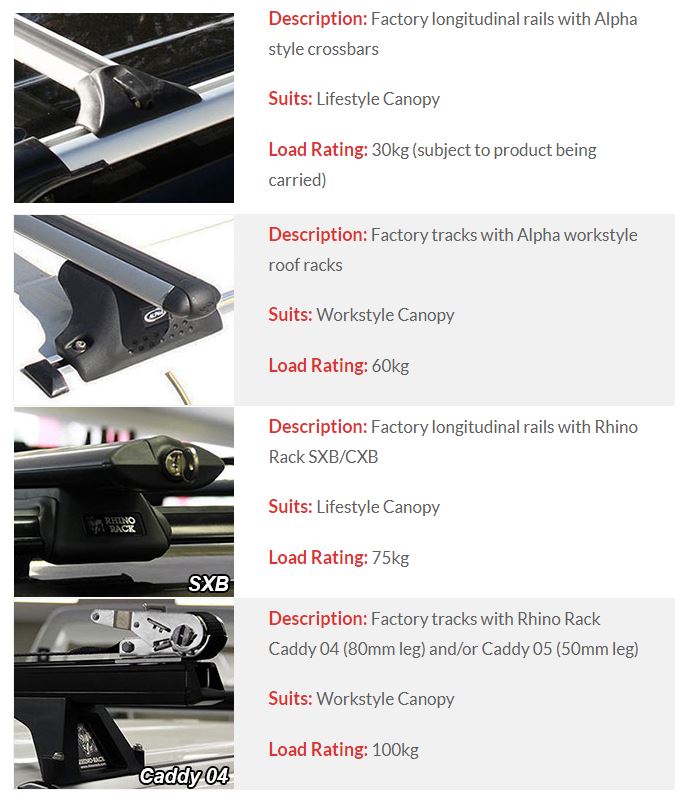

- GSX ute canopy factory bars – 30kg evenly distributed over 2 bars

- CMX ute canopy factory bars – 60kg evenly distributed over 2 bars

- Canopy upgraded with Rhino Vortex bars – 75kg evenly distributed over 2 bars

- Canopy upgraded with Rhino heavy duty bars – 100kg evenly distributed over 2 bars

- For all other vehicle roof rack weight ratings please enquire at www.rhinorack.com.au or enquire with your local store for assistance

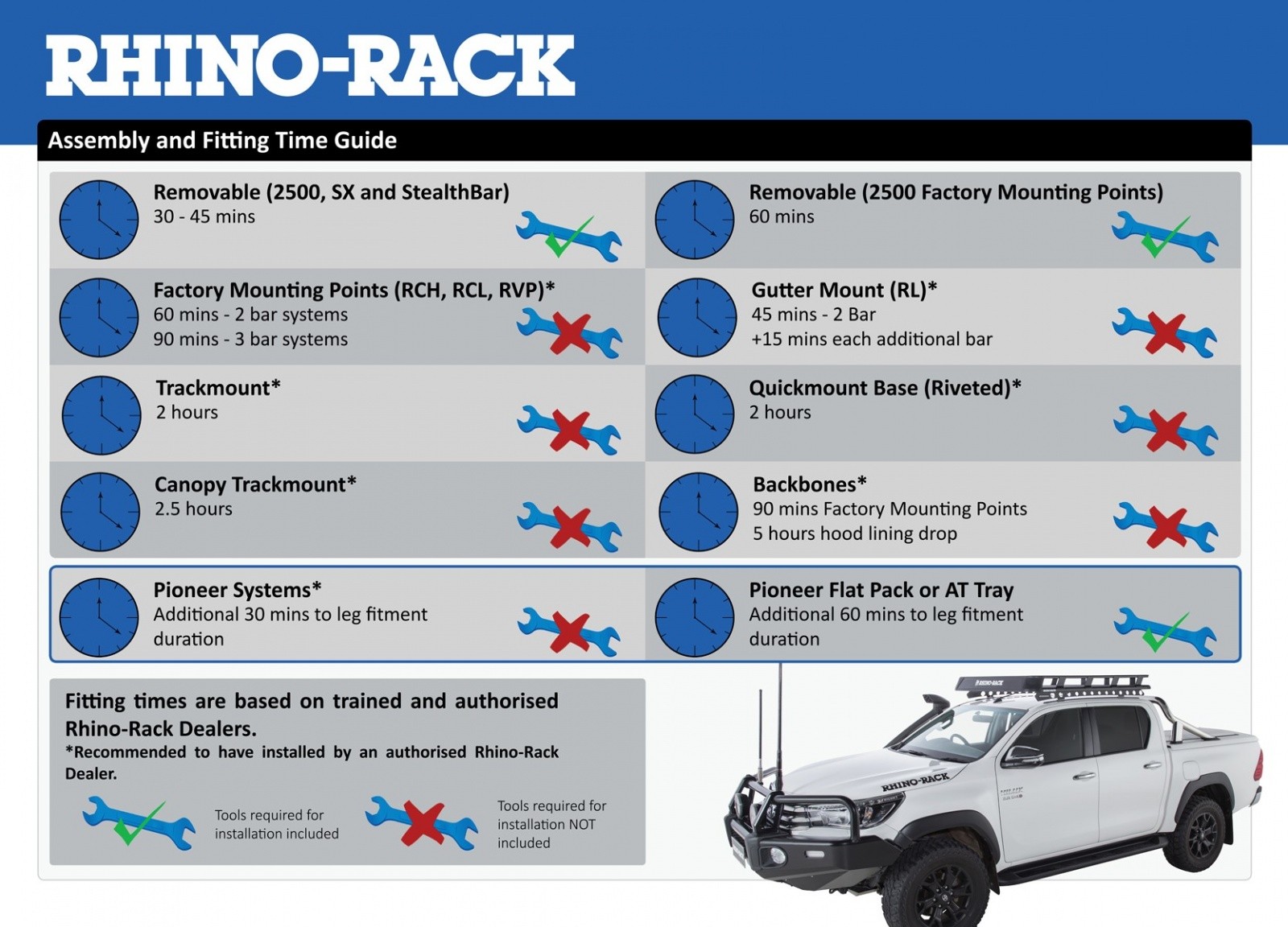

Many of our roof racks can easily be installed at home, however, we recommend some roof rack systems such as track mounts and backbones are installed at one of our facilities. Always follow the instructions and be aware some systems do not come with all the necessary tools for install.

Regardless of who installs your roof racks you should check all bolts and fixtures are tight every 1000km and before every trip. Consider checking more frequently when driving on unsealed surfaces.

In many cases, the roof racks will be compatible with the sunroof version of a vehicle. You should check if there is an “important note” on the roof rack system, as this will detail any considerations like sunroof compatibility. We recommend caution is taken when operating a sunroof with roof racks installed for the first time and be aware of how your cargo may affect the sunroof operation.

Yes, you can find all relevant the documents on the products page under the “documents” tab.

Rhino-Rack accessories are compatible with most roof racks fitted with a channel, however, you should check the roof rack compatibility on the product page to find out if a fitting kit is required.

Yes, check out our MasterKey range you can easily replace the locks on your racks and accessories with one key.

Please contact your local dealer for questions regarding specific vehicle fitments, returns, or product faults.

Load Ratings vary between vehicles, roof type and fixture style. You can find your vehicles load rating from the vehicle manufacturer or on the system by selecting your vehicle from the Fit My Car tool. The cargo load limit will change if the vehicle is driving on-road, off-road or is stationary. The load rating stated on each roof rack system on our website refers to the weight the vehicle roof can handle driving on sealed roads inclusive of the roof rack weight

Our high-end roof racks have been designed with rubber inserts to reduce noise and prevent whistling. Incorrect installation is the most common cause of noisy roof racks. Check your product’s instructions to make sure the rubber strips are installed correctly in the channels both topside and underside of your roof rack bars. The rubber inserts should be cut to the correct length and fitted inside the channel so there are no gaps. Lastly, ensure your end caps are installed and locked before driving. If you want to further reduce wind noise, there are several WIND FAIRING options which can be found on at www.rhinorack.com.au

Firstly, do not take your vehicle through automotive washing stations with your roof racks installed! Hand wash the racks with soap and water. Do not use any abrasive materials. If in doubt check your product instructions.

Most Thule and Rhino-Rack accessories are cross compatible though there may be some exceptions, we recommend you use Rhino-Rack accessories for our bars as they are specifically designed for this purpose. However, if you already have an accessory you want to fit we recommend you visit a Rhino-Rack dealer, they can help you with a fitting kit to fit the accessories to our roof racks.

Check the product roof rack compatibility as some accessories will fit, otherwise, you can use a VA bar adaptor to mount Vortex accessories to your Pioneer System.

Yes, you can order replacement keys through your nearest dealer or you can get replacement locks.

General Tow Bar FAQ'S

- Refer to compliance plate on towbar (under hitch and on side) and towing capabilities of the vehicle. Always check vehicle’s handbook.

- If purchasing a Hayman Reese product also refer to http://www.haymanreese.com.au/products/towbars or enquire with your local store for assistance.

Trailers don’t generally have ABS , there are some aftermarket ABS units available for some trailers and caravans but it is generally not compatible with your standard vehicle ABS and is a standalone system, some vehicle manufacturers are now implementing optional trailer anti-skid devices (Mercedes Sprinter ) check with your vehicle and trailer manufacturer for more information

Ensure all fasteners, hitch, ball and locking pin are tight before every use. Check for excessive rust if you submerge it in water whilst launching a boat. Periodically check wiring operation (lights, breakaway etc ) , grease or lube tow ball if required , check pin for wear.

General Cargo Barrier FAQ'S

All cargo barriers are tested to or comply with Australian standard AS/NZS4304.

Ensure fasteners are always tight and check anchorage points for any obvious damage. If vehicle is in an accident it is recommended that you have your cargo barrier inspected at an authorised Caddy Storage outlet for any advice

Cargo barriers are designed and manufactured and fitted to vehicles according to the Australian standard AS/NZS4304 to ensure your personal safety . Under NO circumstances should a barrier ever be modified as compliance to the Standard cannot be guaranteed to a modified barrier.

Cargo barrier fitting times vary depending on your vehicle . The less complicated cargo barriers can take as little as 30 mins where the more complicated barriers can take up to three hours or more . Please enquire at your point of sale.

Cargo barriers are designed not to impede a vehicles air bags

If your vehicle has been involved in an accident and the cargo barrier has been hit it should be replaced , the structural integrity of steel components cannot be guaranteed to meet the Australian standards in a second accident. We do not recommend fitting second hand barriers as their crash history is unknown and we would not compromise the safety of you or your family.

- The main advantage is that of which this type of cargo barrier is named – Vapour resistant – meaning a great proportion of any vapours carried in the rear of the vehicle will be blocked out from the front occupants. This is very popular now with many larger fleets and their concerns around OH&S.

- It blocks out most noise from the rear compartment of vehicle.

- Improves air conditioning meaning better fuel consumption for the vehicle.

- Polycarbonate clear window – meaning you are NOT looking through a common mesh cargo barrier.

- Polycarbonate window is kinked for light deflection at night time.

- Stops any small items entering into main front compartment in the unfortunate event of an accident.

General Ute Canopy FAQ'S

Generally 2 – 2 ½ hours for a non-central locking canopy and 3 – 3 ½ hours for a central locking canopy. There are other factors that may contribute to extra time such as if particular items need to be removed from the vehicle to install the ute canopy such as sports bars, ute lids etc. Please also note that this time does not take into account other factors such as installing other items with the ute canopy such as roof racks etc.

Approx. 95 – 100kgs.

Refer to ute canopy care guide. Most importantly ensure canopy securing clamps are tightened periodically.

2m x 1.7m x 0.7m

This really depends on many factors ranging from vehicle type, 2WD or 4WD, Canopy type, whether vehicle has roof racks or not. Generally height clearance on average is around the 1.9 – 2m mark.

Our Alpha canopies are a hand laid fibreglass one piece shell finished in automotive 2 pack paint, all locks and fitting hardware are either anodised aluminium or stainless steel construction

The reinforced strength is built into the design and thickness of materials used to manufacture the ute canopy taking away the need for internal roof rack supports

Ute tubs are generally NOT fully sealed so there is no reason why you cannot although the space will be limited, most canopies have an internal handle to open the canopy from inside.

We do not endorse the fitting of roof top campers. We are aware it has been done by individuals with no reported issues but we have never tested the canopy to meet the requirements of a roof top camper so it is an unknown risk fitted to your vehicle. Fitting of a roof top camper is done at your own risk and may void warranty.

Refer to ute canopy care guide. Most importantly ensure canopy securing clamps are tightened periodically.

The actual tubs of most utes are not dust proof. Our ute canopies have a full rubber mounting seal and rear tailgate seal but most dust will enter via the vehicle tailgate and production gaps in the tub body as these generally don’t have seals from the vehicle manufacturer. Ute tailgate sealing strips are available as an option for most models which will assist with any minor dust issues. Contact your local Caddy branch for more information.

Our ute canopies are weather proof not waterproof. Different manufacturing tolerances from vehicle manufacturers need to be addressed along with optional tailgate sealing strips if you are encountering any water leaks. Canopies should not be exposed to high pressure cleaners or automated car washes. Please refer to how to care for your canopy brochure, all of our canopies have a large rubber seal between the deck and canopy and generous side door seals as well as an internal drain feature for the rear door seal.

Windows Tints will be 30% i.e. 70% light transfer.

Front Cabin Sliding window will be clear Glass.

Yes however this will be a custom purchase in which may take 12 – 14 weeks arrival time.

Yes however this will be a custom purchase in which may take 12 – 14 weeks arrival time.

Sliding windows are secured by an internal latch

Approx. 12 – 14 week lead time however in some cases this can be less, please consult with your local branch for more detailed information.

12 months

Manufacturing faults. Installation and electrical. Locks. NOTE Broken glass not considered as warranty.

Yes – canopies are colour coded with a quality automotive two pack paint process.

Ute canopies once installed are generally not removed again unless the vehicle is sold or the canopy no longer required. The clamp system between the ute canopy and tub of the vehicle are a non-drill fit so it’s of course possible to be removed however not a 1 x person job to actually lift the ute canopy off the vehicle.

Unfortunately not hence why ensuring to make the correct decision on adding in central locking at your time of purchase

Suggest a sliding window canopy. We can also add to the sliding windows and sliding window guard (perforated powder coat sheet metal) which will allow your sliding window to stay open for air circulation purposes and the guard will stop the possibility of your animal occupant escaping. A roof vent can also be added to the roof of your canopy for extra circulation.

Albeit it is most likely illegal we highly recommend not too. Of course possible if carrying something long and tailgate needs to stay open however this will place added pressure to the gas struts and also increase the chance of glass breakage.

Again this is your local store dependent. Suggest to check with your local sales person or alternatively check for latest specials on our website.

All ute canopies have standard roof bars or roof rails (depending on the canopy) ready to accept roof racks. Load ratings for roof racks are dependent on the type of bars installed on the canopy.

Aluminium Canopy FAQS

Standard – Stainless door continuous hinge

Standard – Stainless flush mount door locks with no visible fasteners and covered key lock

Standard – 3 x Reinforced Gull wing doors

Standard – Rubber flooring

* Single cab body (not incl. tray) 250 kg

* Extra cab body (not incl. tray) 175 kg

* Dual cab body (not incl. tray) 160 kg

* Tool box 1800mm – 68.5 kg

* Tool box 1450mm – 52.5 kg

* Tool box 1200mm – 45 kg

* Underbody tool box – 14.5 kg* Trundle drawer 1700mm – 87 kg

* Trundle drawer 1500mm – 79.5 kg

- Dual cab tray– 54kg

- Extra cab tray – 64kg

- Single cab tray – 74kg

* Single cab body (not incl. tray) 250 kg

* Extra cab body (not incl. tray) 175 kg

* Dual cab body (not incl. tray) 160 kg

* Tool box 1800mm – 68.5 kg

* Tool box 1450mm – 52.5 kg

* Tool box 1200mm – 45 kg

* Underbody tool box – 14.5 kg

* Trundle drawer 1700mm – 87 kg

* Trundle drawer 1500mm – 79.5 kg

Hinges open minimum 105 maximum 120 degree, with a 610 – 620mm side door opening span.

Max height with side door open : 217 mm

Quotation, Payment & Finance FAQ'S

We do offer that we can match or better any reasonable quotation however product or fit out comparability needs to be the same.

Online payment via credit card (with exception of Amex and Diners), Bpay, direct deposit, cash, cheque (Criteri dependant)

If your vehicle is in a crash please contact your insurance company immediately. Cargo barriers should be replaced, any shelving anchorages checked, ute canopy mounting points checked or replaced occupied seat belts replaced, and seat anchorages checked or replaced to ensure they still comply with the relevant ADRs, like your vehicles SRS systems many of these components are designed for a once off use in an accident and must be replaced after an accident to ensure continued compliance with the relative laws and standards, please contact your local branch for more specific information.